We Accelerate

An Efficient, Electric and Decarbonised Future

Advanced Engineering

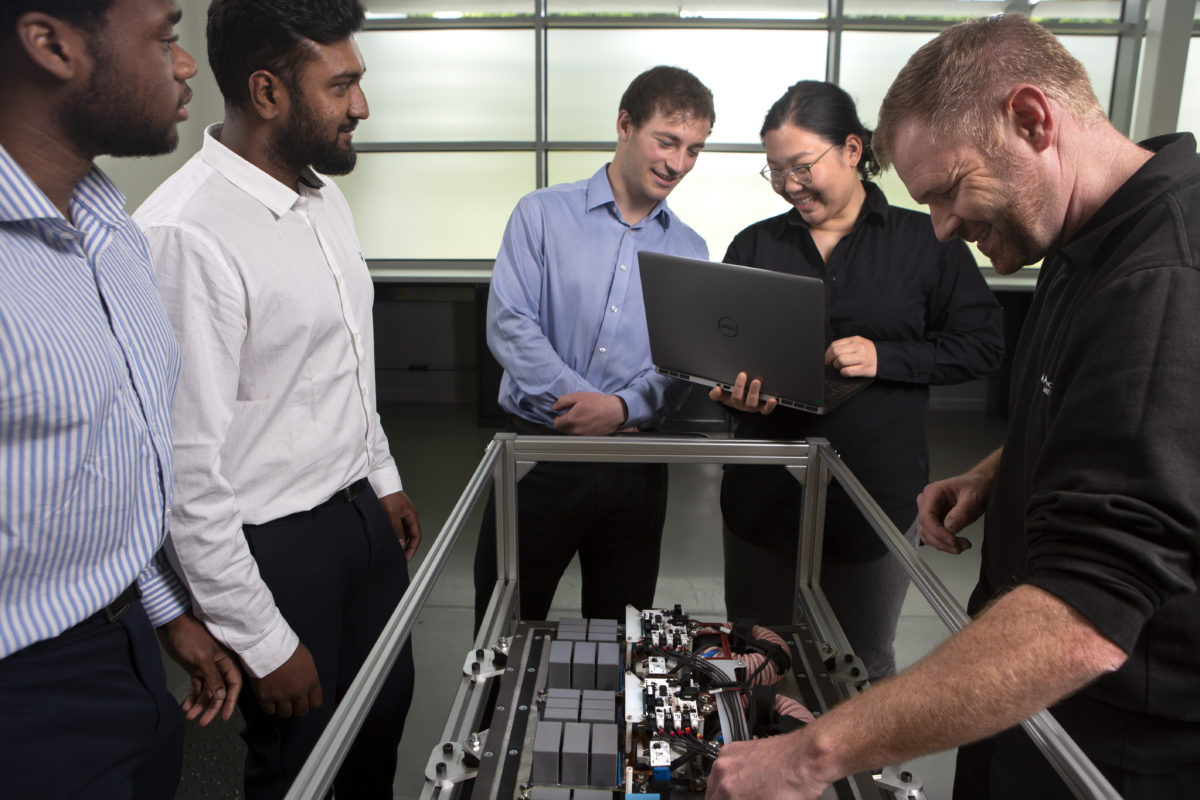

WAE exists to accelerate the advantage and impact of our clients.

We’re a technology and engineering services business, applying world-class technical innovation, engineering, testing and manufacturing services to deliver energy efficient performance.

Our people are experts in electrification and battery technology, aerodynamics and thermodynamics, performance and specialist low-volume manufacturing. We operate across a wide range of sectors from automotive and motorsport, aerospace and defence, rail, off highway, and energy. We work in close collaboration with our customers and partners to meet the key engineering challenges of the 21st century – focusing on mobility, energy storage sustainability and efficiency.

Our Solutions

We bring together cutting-edge technological advances with the industry’s best engineers. We apply the precision and speed to market that comes from our experience in the ultra-competitive world of motorsport; delivering innovative solutions across energy management and control, lightweight structures, automotive and aerodynamics.

Ensuring a Sustainable Future

Sustainability and a drive for efficiency, electrification and a better world has always been at the heart of what we do.

Today, as part of Fortescue Group, we are extending our impact, supporting a sustainable, decarbonisation strategy through our world-leading advanced battery technology and energy storage solutions to bring the world efficient and electric solutions and technology that ensures a more sustainable future.

Our Products

Our innovative products enable superior performance through increased range, power and efficiency across the most demanding of applications. Our range covers a number of platform functions including power, control and communications, where functional safety and reliability are key.

Our whole-system integration approach means we can supply everything from individual control units and sensors, through to an all-electric drivetrain.

Battery Management Hardware

Elysia® Battery Intelligence

Battery

Modules

Vehicle

Controllers

Power Coversion

Latest News

Careers

Our people are what make our business unique. We employ the best engineers and the smartest brains to develop new, creative and innovative technologies to change the world; always seeking new and better ways of doing things, pushing the boundaries of what’s possible.

We all pull together, working as one team, empowered to be the best we can.

Get in Touch

If you are looking for further information or want to discuss anything with us, please feel free to contact us here.